المنتجات الساخنة

Tips for Crusher Maintenance Thomasnet

网页2018年11月28日Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies

Contact

Industrial Solutions Jaw crushers ThyssenKrupp

网页Call on our services and you can count on a wealth of experience and constant innovative drive. As a leading manufacturer of machines and plants for the aggregates and mining

Contact

Jaw crusher maintenance : PitQuarry

网页2014年2月1日Check jaw dies daily, making sure bolts are kept tight. Check cheek plates for any excessive wear that may affect the mainframe of the jaw. Monitor flywheels for

Contact

Jaw crusher maintenance Henan Deya

网页The crushing chamber jaw plates are loose, the fixing bolts are loose or broken. Stop the jaw crusher, check the fixation of jaw plates, and use hammer to tighten the wedge on plates, then fasten the bolts or replace

Contact

Jaw Crusher Maintenance and Inspection Luoyang Dahua

网页2018年10月16日The maintenance and inspection of jaw crusher mainly focus on below aspects: (1) Check the temperature of the bearing. The temperature of bearing shall not

Contact

Main points of repair and maintenance of jaw crusher

网页2021年8月13日Jaw crushers, commonly known as jaw crushers, are widely used for medium-size crushing of various ores and bulk materials in mining, smelting, building

Contact

4 Types of Stone Crushers' Maintenance and

网页2023年2月15日The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the

Contact

Operation and Maintenance in Jaw Crusher Using Process

网页Operation and Maintenance in Jaw Crusher Using Process by Wade Wu Medium Write Sign up Sign In 500 Apologies, but something went wrong on our end. Refresh the page,

Contact

Laboratory and pilot plant Primary Jaw

网页Essa JC2000 Jaw Crusher a “workhorse” engineered to be the industry standard crusher in the geochemistry laboratory; Ease of maintenance. The crusher has a number of features which make it easy to maintain

Contact

MBMMLLC: Jaw crusher maintenance and

网页2015年4月1日We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap...

Contact

Industrial Solutions Jaw crushers ThyssenKrupp

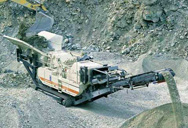

网页Jaw crushers Crushing made easy Our solutions for the hardest jobs Fields of application and design characteristics They are used in mines and quarries as primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveying.

Contact

Jaw Crushers JW Series Corporation

网页Simple maintenance Jaw-faces are retained by a mechanical wedge locking system removing the need to access bolts behind the MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155-480 (140-435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder 200 hp

Contact

Jaw crusher maintenance Henan Deya Machinery Co., Ltd

网页2022年7月22日1.5 Inspection and Maintenance. The daily inspection and maintenance of the jaw crusher are mainly as follows. (1) Check the heat of the bearings, make sure it is within the normal range indicated by Deya Machinery’s operation manual. (2) Check whether the lubrication system is working properly. (3) Check the quality of the oil return pipe.

Contact

Jaw crusher maintenance Henan Deya

网页Jaw crusher operation and maintenance. Jaw crushers are generally installed on top of the concrete foundations. Take into consideration of the weight of jaw crusher, the tough working conditions and the high inertia

Contact

Common faults and maintenance methods of jaw

网页2021年10月8日Jaw rock crusher adopts special grade car grease or 3 lithium base grease, adding the appropriate amount of grease every 400 hours of work; after 2000 hours of work, open the main shaft assembly

Contact

Cedarapids OperationMaintenance Manual Jaws

网页OperationMaintenance Manual. JAW CRUSHERS Bolted Bearing Blocks Pull-Type Bearing Sleeves. A Company 22783 (8/02). A Company. To the OwnerOperator: We have tried to provide information that gives our customers a clear understanding of equipment construction, function, capabilities and requirements.

Contact

Manual Telesmith 30-42 PDF Rope Belt (Mechanical)

网页Before performing any lubrication, maintenance, adjustment, or repairs. 2. Before removing spilled materials. 3. Before clearing jams or working inside the machinery. 4. If any unusual noises or sudden changes in operation are noticed. • Stay clear of feed and discharge areas and other places where falling rock is present.

Contact

Main points of repair and maintenance of jaw crusher

网页2021年8月13日The jaw crusher adopts Mobil Car Grease Premium or 3 Lithium-based grease. Appropriate amount of grease is added every 400 hours of work; after 2000 hours of work, the main shaft assembly is opened to clean the bearings; the general work is 7200 hours to replace the new bearings.

Contact

Laboratory and pilot plant Primary Jaw

网页Essa JC2000 Jaw Crusher a “workhorse” engineered to be the industry standard crusher in the geochemistry laboratory; Ease of maintenance. The crusher has a number of features which make it easy to maintain

Contact

MBMMLLC: Jaw crusher maintenance and

网页2015年4月1日We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap...

Contact

Industrial Solutions Jaw crushers ThyssenKrupp

网页Jaw crushers Crushing made easy Our solutions for the hardest jobs Fields of application and design characteristics They are used in mines and quarries as primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveying.

Contact

Jaw Crushers JW Series Corporation

网页Simple maintenance Jaw-faces are retained by a mechanical wedge locking system removing the need to access bolts behind the MJ42 JW42 (30” x 42”) Jaw Crusher, 40” x 14’ Feeder 150 hp (110 kW) 155-480 (140-435) (3) 40ft shipping containers MJ55 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ Feeder 200 hp

Contact

Jaw crusher maintenance Henan Deya Machinery Co., Ltd

网页2022年7月22日The daily inspection and maintenance of the jaw crusher are mainly as follows (1) Check the heat of the bearings, make sure it is within the normal range indicated by Deya Machinery’s operation manual. (2) Check whether the lubrication system is working properly. (3) Check the quality of the oil return pipe.

Contact

Cedarapids OperationMaintenance Manual Jaws

网页OperationMaintenance Manual. JAW CRUSHERS Bolted Bearing Blocks Pull-Type Bearing Sleeves. A Company 22783 (8/02). A Company. To the OwnerOperator: We have tried to provide information that gives our customers a clear understanding of equipment construction, function, capabilities and requirements.

Contact

Common faults and maintenance methods of jaw

网页2021年10月8日Jaw rock crusher adopts special grade car grease or 3 lithium base grease, adding the appropriate amount of grease every 400 hours of work; after 2000 hours of work, open the main shaft assembly

Contact

Fine Jaw Crushers

网页Essa® JC1250 Jaw Crusher. Our Essa JC1250 Jaw Crusher is small but strong. We modelled it off the tried and tested larger JC2501 after extensive research and development. For a compact crusher, our JC1250 can handle a high workload up to 5 kg samples comfortably. It has impressive throughput up to 140 kg/hr.

Contact

Main points of repair and maintenance of jaw crusher

网页2021年8月13日The jaw crusher adopts Mobil Car Grease Premium or 3 Lithium-based grease. Appropriate amount of grease is added every 400 hours of work; after 2000 hours of work, the main shaft assembly is opened to clean the bearings; the general work is 7200 hours to replace the new bearings.

Contact

EQUIPMENT AND MAINTENANCE 911 Metallurgist

网页Keywords: Equipment, Maintenance, Crushers, Jaw crushers, Rock breakers, Refurbishing, Choking, Lubricating systems. field from the late 1800s to the early 1900s. In 1910 the largest gyratory cru shers built had 48-inch openings. However, about this time the jaw crusher came to life when the Power and Min

Contact